Minimise downtime with predictive machinery maintenance

In addition to the sale of electric drives, Motoren Françoys also specialises in predictive maintenance.

Through proactive maintenance for your machinery you get insight into the condition (condition monitoring) and potential future damage or faults, which allows you to maximise the service life of your equipment.

Types of predictive maintenance

There is no single golden formula for predictive maintenance for your machinery. Motoren Françoys has solid knowledge and experience to select the method of measurement for condition monitoring that yields the fastest, most economical and most reliable results.

Vibration measurements are done in various ways at Motoren Françoys:

- We make use of a VSHOOTER to measure the overall values. This can be done at your site or in-house at our workshop.

- The Shock Pulse Method (SPM) makes it possible to determine the machine’s bearing condition and to evaluate it based on the speed and shaft diameter.

- A vibration analysis gives us insight into the most common faults, such as imbalance, construction or foundation problems, loose components or bearing damage. The vibration levels that were measured are analysed and compared with the ISO recommendations.

Regular visual carbon brush inspections tell us about the condition of the carbon brushes on your machinery and whether they need to be replaced.

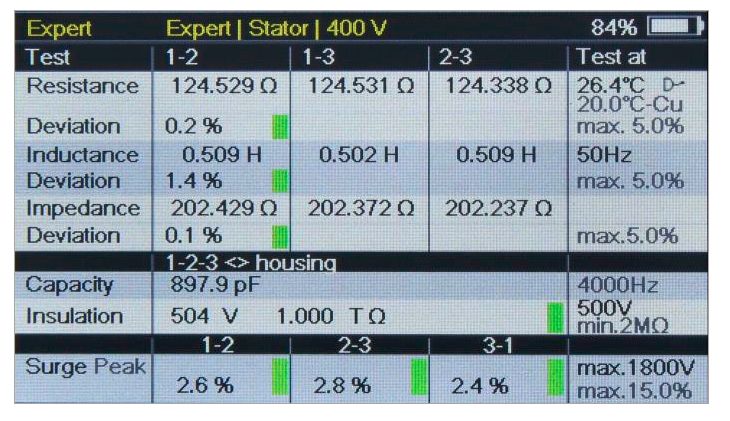

A regular electrical analysis can prevent AC and DC motors from becoming faulty and can therefore also avoid downtime. This requires preventive cleaning and reimpregnation where necessary.

The Dynamic Motor Analyser allows us to diagnose the complete drive train in operation. We measure and calculate electrical and mechanical parameters such as Cos Phi, harmonics, speed, efficiency, energy costs, power supplies, torque and more.

Leave the maintenance of your machinery in the hands of Motoren Françoys

We can be of service to you in the design, follow-through and implementation of your preventive maintenance system. If required, we can combine that with periodic inspections of your machinery or installation. If necessary, we will in that case start by compiling a one-time full or partial inventory of all your equipment and provide a clear coding system. The data we collect is then organised accordingly and stored in a database.

Want to maximise the service life of your equipment?

Contract Motoren Françoys for predictive maintenance of your machinery.